Machining the Packing Glands

The original plans, and the prototype, have two studs on the heads, and

tightning a pair of nuts pressed on the packing glands which in turn

presses on the packing

material, sealing the

rods. There are lock nuts that prevent the other nuts from vibrating

loose.

After fiddling with tightning the packing on the other models in our

locomotive roster, and after urging from Gorden, I decided to adopt a

threaded packing gland nut, as Gorden did on his Shay engine.

The first step is to choose the size and thread pitch. This usually

involves intense engineering. That means choosing what taps are on

hand. Gorden had two taps the fit the bill. One 5/8 x 24 TPI, and the

other 3/4 x 24 TPI. Since I was going to thread the Packing Glands Nuts

on the lathe,

the same threads per inch made a lot of sense. Not to mention the

adjustment of the valve and cylinder packing nuts will be similar.

Valve Packing Gland Nut

Cylinder Packing Gland Nut

Even

though I had a tap that what the correct size, I started the treading

process on the lathe. This will help keep the treads concentric with

the bore. I will finish the thread depth with the tap.

This

show the completed Cylinder Heads.

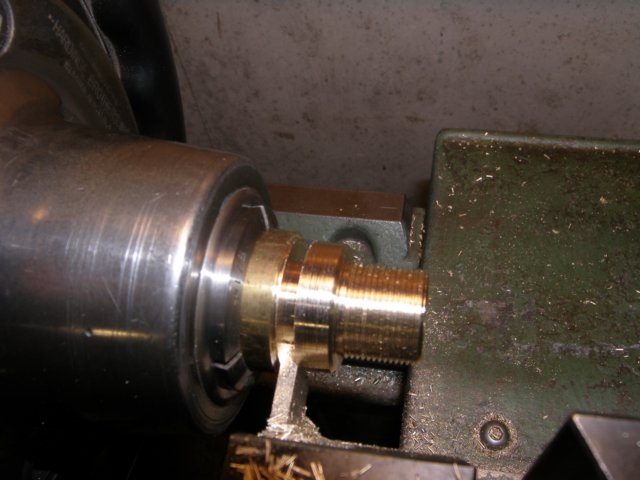

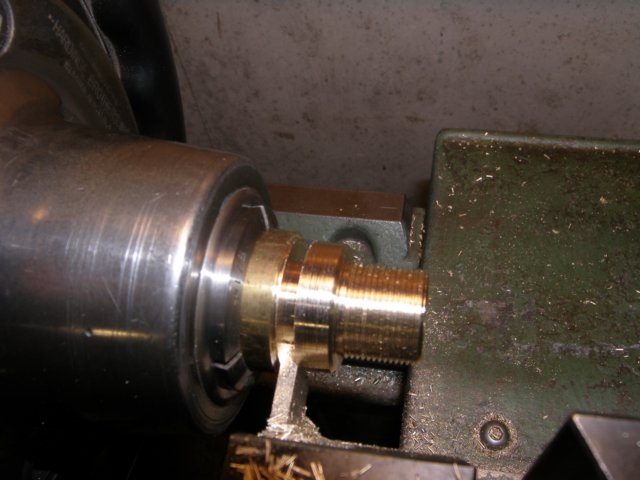

Here

is the almost completed Packing Gland Nut. I fininhed the part by

facing the side just parted off, and then drilled the aqdjustment

holes. See more pictures here.

Here

is the Valve Head with the Valve Packing Gland Nut installed.

Karl

Kobel

With

the help of Matthew Kobel and Gordon Carlson

(see his

work on http://www.locogear.com/page15.html).