6-Dec-2005

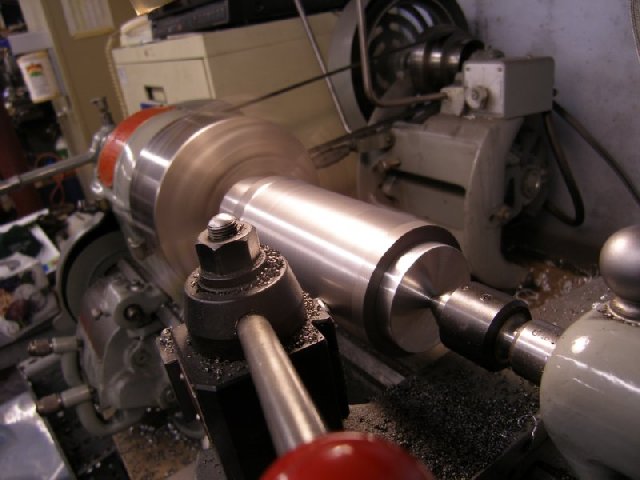

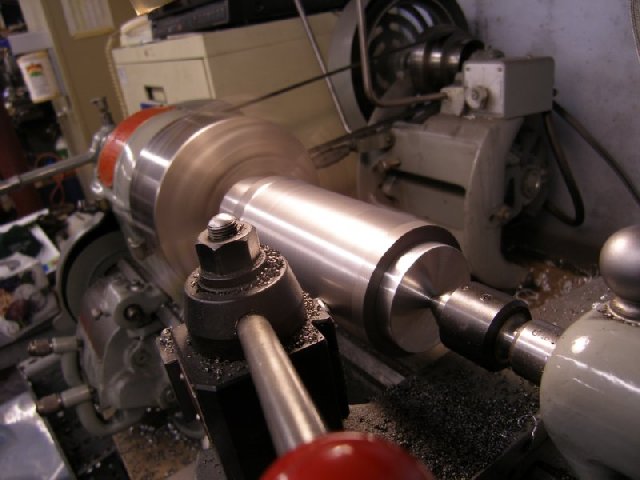

An aluminum mandrel was turned on the lathe to be a tight slip fit for the honed cyclinder liners. Then a hole was drilled and tapped for 1/4-20 in the to-be cutoff section of the liner to drive it. Then the outside of the liner was turned for a 0.0015 press fit in the cyclinder opening. Since the opening was honed parallel, I could be assured of a good fit as long as the lathe was adjusted to cut a parallel diameter. Gorden spent quite a bit of time making sure the tailstock setover was adjusted correctly.

Created with Web Album Generator